Here is a video of Laimer explaining how his clock works and how he designed it:

All in total Laimer 3D printed more than 50 individual parts to build his clock, and only needed to use a small amount of pins and screws to hold everything together.

#3d printed mechanical clock software#

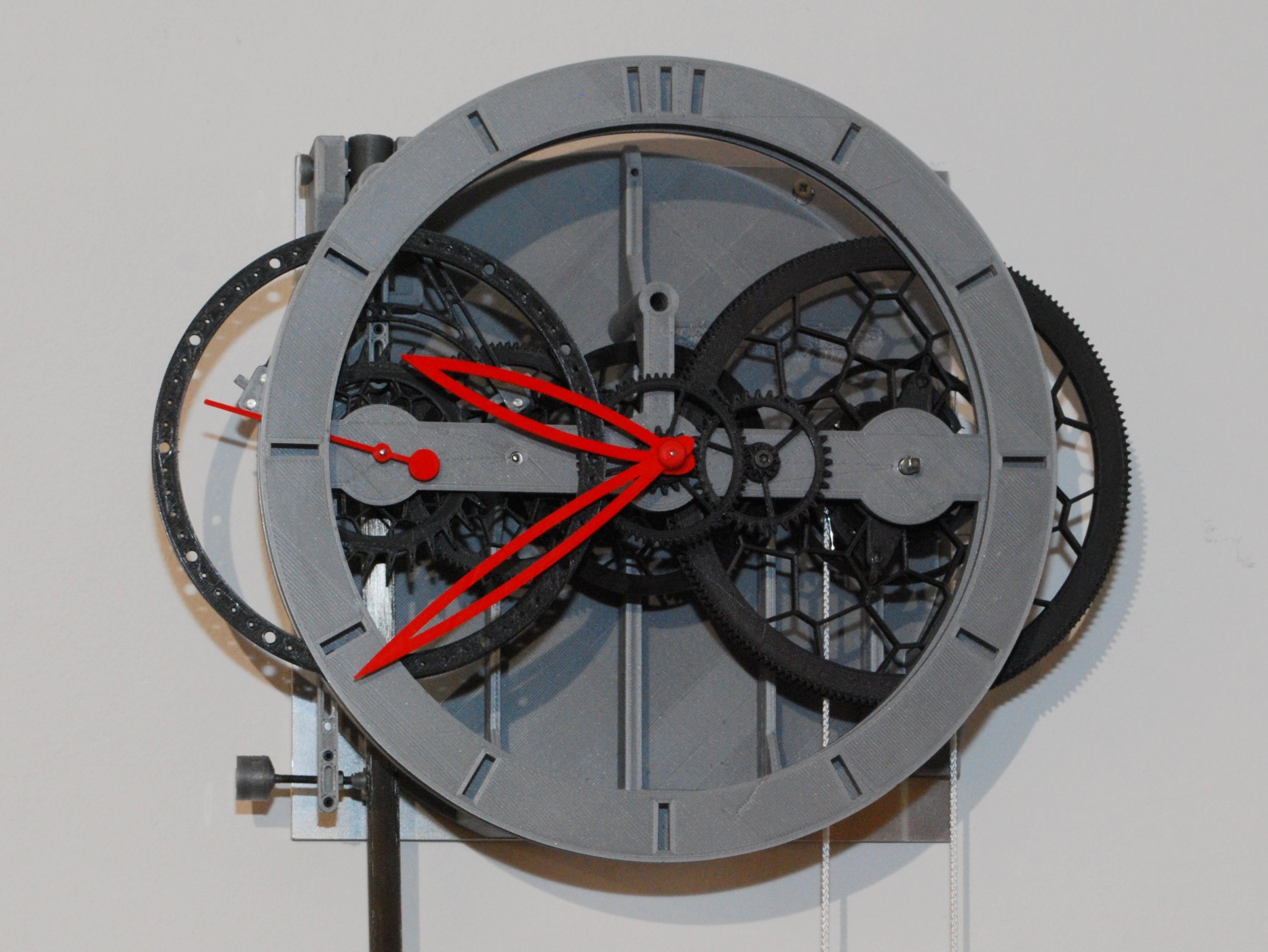

The clock was designed in Autodesk’s Fusion 360 design software suite and was tested virtually to make sure that all of the parts would function as envisioned. I’ve seen a few larger clocks and simple gear mechanisms 3D printed, but this is the first time that I’ve seen a timekeeping device as complex and difficult to engineer as Laimer’s clock with a tourbillon. The case itself was printed in PETG while all of the internal gears and mechanisms were printed with standard PLA. The parts weren’t printed on an industrial 3D printer that makes end-use parts, but rather in his home on an Ultimaker 2 desktop 3D printer. Laimer’s clock is a marvel of clock design and an example of his 3D printing prowess. The clock was designed in Autodesk Fusion 360.īut Swiss engineer and Thingiverse user Christoph Laimer has successfully fabricated a working clock with a tourbillon that is made entirely from 3D printed gears, mechanisms and components. Producing the small and delicate parts used to make a working tourbillon using traditional materials, usually solid metals, but sometimes even precious metals, is extremely difficult, but using 3D printed components to make a functional tourbillon is a remarkable achievement. Only the most skilled of watchmakers can create one that is accurate, and because they are so uncommon they are often shown off essentially as a status symbol or a sign of wealth. The art of watchmaking in this day and age is itself becoming a novelty, so watches with real tourbillons are even rarer and usually are only featured on very expensive watches due to their incredibly complex and difficult to engineer mechanics. Even most modern automatic watches don’t use real tourbillons anymore, and in fact horologists (people who study the measurement of time) have long debated whether they actually helped accuracy or were merely an expensive and complicated decoration.

#3d printed mechanical clock series#

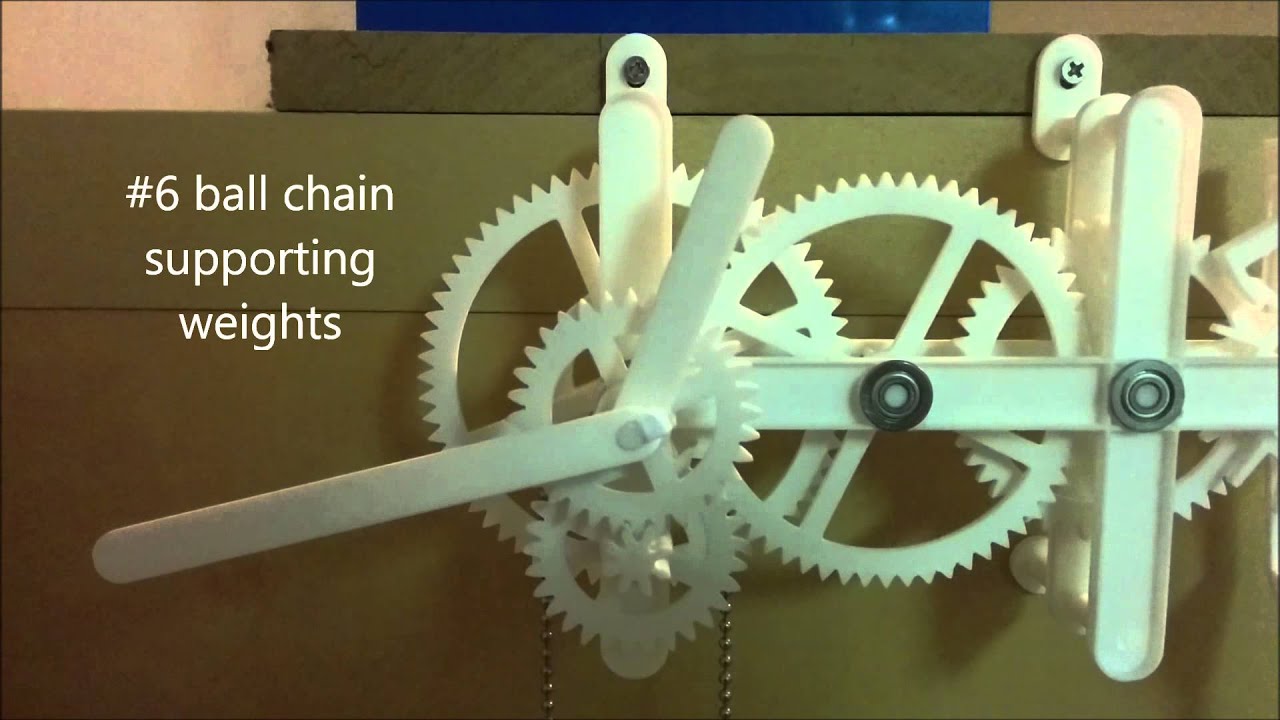

Basically if you see a battery operated watch that has what looks like a series of gears exposed on the face then it is mimicking the look of an automatic watch with a tourbillon monitored second hand. In an era when most watches are battery operated tourbillons are pretty rare, however faux tourbillons are quite common. In case you’re not familiar with what a tourbillon is, it is a mechanical component to a watch that prevents gravity from slowing down the watch and reducing accuracy. The actual needed weight depends a lot on the friction of the whole system.Christoph Lamier’s working clock with a tourbillon. For version d) I'd probably need a weight of 2.3kg. My clock works well with version c) and 1.2kg weight. There are STL-versions with 2 x 2 combinations for the winding:Ī) Simple Ratchet v1: 4.22 revolutions per hour (weight moves 26.5cm/h)ī) Simple Ratchet v2: 2.25 revolutions per hour (weight moves 14.1cm/h)Ĭ) Planetary Drum v1: 3.01 revolutions per hour (weight moves 18.9cm/h)ĭ) Planetary Drum v2: 1.61 revolutions per hour (weight moves 10.1cm/h)

1 x Balance wheel: 1.5mm diameter, 40mm length.In Simplif圓d there is another useful parameter: "process settings / advanced / other / horizontal size compensation". In order to compensate this, the material flow could be increased (overextrusion).

when printed with a newer generation printer, parts are most likely too loose. The 3d-files are optimised for older printers with more inaccuracy in xy, or a badly guided z axis. Some parts require a loose clearance (hollow shaft for hours and minutes), other parts require a press fit (hands). The winding has a nested planetary gear, which allows that the clock continues to run, while winding up.Įverything is 3d-printed (even the spiral spring), except e few small screws, some metal pins, the cord, and the lead for the weight. This video shows the clock and the building process (actually with a simpler ratchet-winding): The clock shows Seconds, Minutes, and Hours. The clock has an anchor escapement, and a balance-wheel with a spiral spring. It's possible to create intelligent, living things. This mechanical clock demonstrates that 3d-printing is not just for decoration.

0 kommentar(er)

0 kommentar(er)